发明申请

US20160023907A1 Process for Producing Fine, Morphologically Optimized Particles Using Jet Mill, Jet Mill for Use in Such a Process and Particles Produced

有权

基本信息:

- 专利标题: Process for Producing Fine, Morphologically Optimized Particles Using Jet Mill, Jet Mill for Use in Such a Process and Particles Produced

- 专利标题(中):使用喷射式粉碎机生产精细形态优化的颗粒的方法,用于这种工艺中的喷射式粉碎机和生产的颗粒

- 申请号:US14774242 申请日:2014-03-11

- 公开(公告)号:US20160023907A1 公开(公告)日:2016-01-28

- 发明人: Werner HANDL

- 申请人: TOTAL RESEARCH & TECHNOLOGY FELUY

- 优先权: DE102013004223.2 20130311

- 国际申请: PCT/EP2014/054739 WO 20140311

- 主分类号: C01B31/04

- IPC分类号: C01B31/04 ; C01B31/00 ; C01B21/064 ; B02C19/06 ; B02C23/06

摘要:

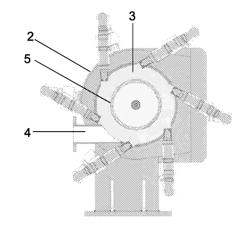

A process for producing fine particles with a high aspect ratio and/or a low specific surface area includes use of a jet mill. An alkaline grinding aid is added to a grinding gas before the grinding gas is fed into a grinding chamber of the jet mill. The process includes micronisation of particles of layered structure material having an interplanar distance ranging from 0.30 nm to 0.40 nm as measured by X-ray diffraction method.

摘要(中):

用于生产具有高纵横比和/或低比表面积的细颗粒的方法包括使用喷射磨机。 在研磨气体进料到喷射式粉碎机的研磨室之前,将碱性助磨剂加入到研磨气体中。 该方法包括通过X射线衍射法测量的具有0.30nm至0.40nm的面间距离的层状结构材料的颗粒的微粉化。